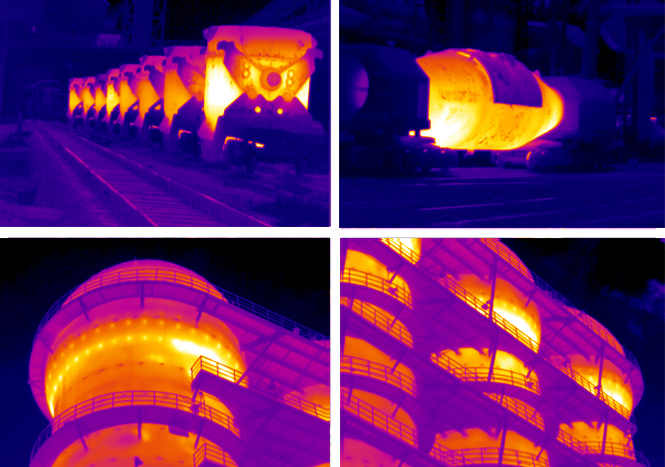

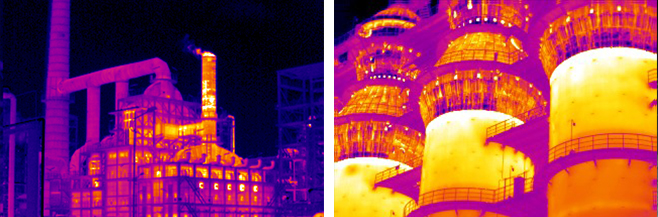

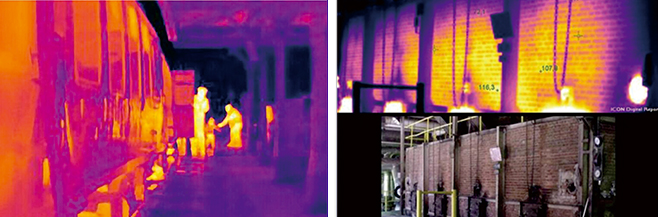

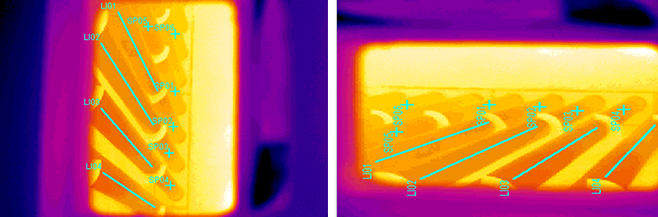

Many important equipments in petrochemical production work under high temperature and high pressure conditions, lurking some flammable and explosive hazards, requiring strict online monitoring of the production process to eliminate hidden dangers in time. Using infrared temperature measuring thermal imager can detect product transmission pipelines, refractory and thermal insulation materials, corrosion, cracking, thinning, clogging and leakage of various reactors, etc., and can quickly and accurately obtain the two-dimensional temperature of the equipment and material surface distributed. Examination of the loss, cracks and wear of refractory materials in the furnace body, gas and dust exhaust pipes, reactor tanks and transfer lines is very effective in preventing accidents and reducing energy consumption.

In order to ensure the normal operation and safe production of the chemical petroleum depot, in addition to improving the safety awareness of the staff and the safety of the equipment, it is particularly important to establish a safety precaution system to achieve real-time collection and data analysis of on-site data and equipment information to improve emergency response Response processing capacity and response speed, safety of employees and surroundings, provide accurate and timely first-hand information for safe production and command and dispatch. Therefore, the importance of video surveillance in the entire security system is particularly prominent. In view of the particularity of the chemical industry, the security of intelligent video surveillance technology in the chemical industry is promising.

1.Petrochemical plant safety leak detection

2.Security of key departments, buildings, warehouses

3.High temperature and pressure state detection

4.Petrochemical production testing